Packaged food waste - no problem

Food waste is an expensive commodity, and the pressure to recycle more sits firmly with the business creating or managing it. Packaged food waste is often so problematic that businesses simply consign it to landfill. The solution is the i-fdr depackaging system which separates the packaging from the food with no need for staff to segregate it. So packaged food producers and retailers can benefit from everything the id-r systems offer; cost savings and even possible revenue opportunities. Scroll down now to find out more about this fantastic add-on. By employing depackaging as part of an integrated food waste management solutions , our i-fdr depackaging system, can separate food waste from packaging. Contaminant is an oft-hurled epithet at food waste composting and anaerobic digestion facilities, reflecting processors’ frustrations at having to clean up the incoming organics stream to minimize equipment downtime, and preserve product quality and price points. Food products come packaged in an almost infinite variety of materials, shapes, weights, and densities. Almost all packaging is a contaminant, including (in some views) the astm-compliant compostable plastics that are beginning to capture market share. Packaging varies from the expanded polystyrene foam used to make the small sandwich tray to

read more →

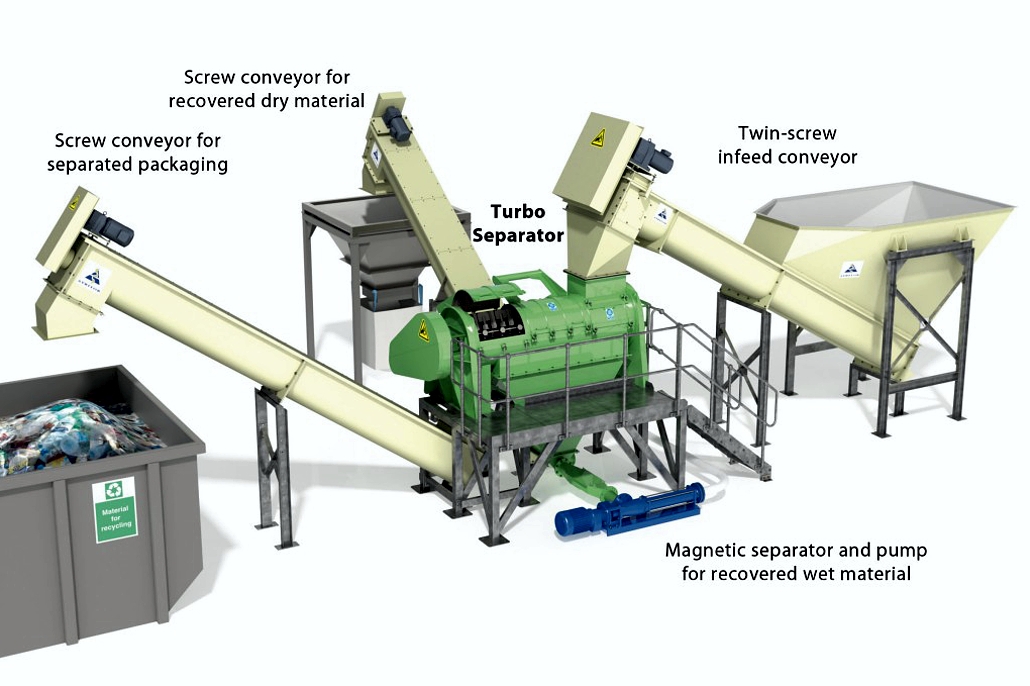

WASTE DEPACKAGING MACHINE PROCESSING

The dominator waste depackaging processing machine, waste handling whilst separating outer packaging from inside waste, enabling you to reuse and recycle waste that would have otherwise been sent straight to landfill. Waste food is a fast-growing issue for many companies, councils and manufacturers. Much of the waste generated cannot be accepted straight in to the manufacturers process; but requires some degree of separation or removal of outer waste packaging before it can be processed. The waste depackaging process is crucial in getting suitable food waste material into anaerobic digestion plants and is also used in putting food back in to animal feeds. Biogen own and operate tiger machines at three of our existing food processing facilities; millerhill, halstead and basingstoke. The tigers operate at the front end of our food waste anaerobic digestion plants. They are designed to process the raw material at the front end to separate the organic and non-organic material. The non-organic material which is mainly packaging material goes for either disposal or re-use as an alternative fuel and the organic material (biomass) is pumped forward into a holding tank and then further on to pasteurisation and digestion in the sealed tanks to generate a methane gas

read more →