WASTE DEPACKAGING MACHINE PROCESSING

by Admin

Posted on 01-08-2022 09:01 PM

The dominator

waste

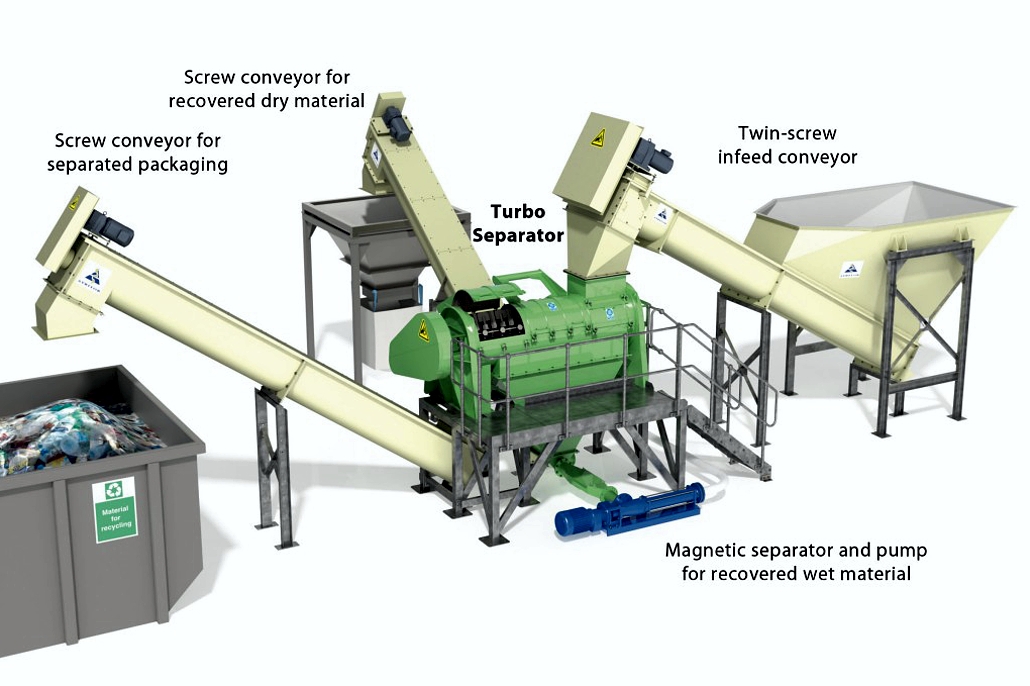

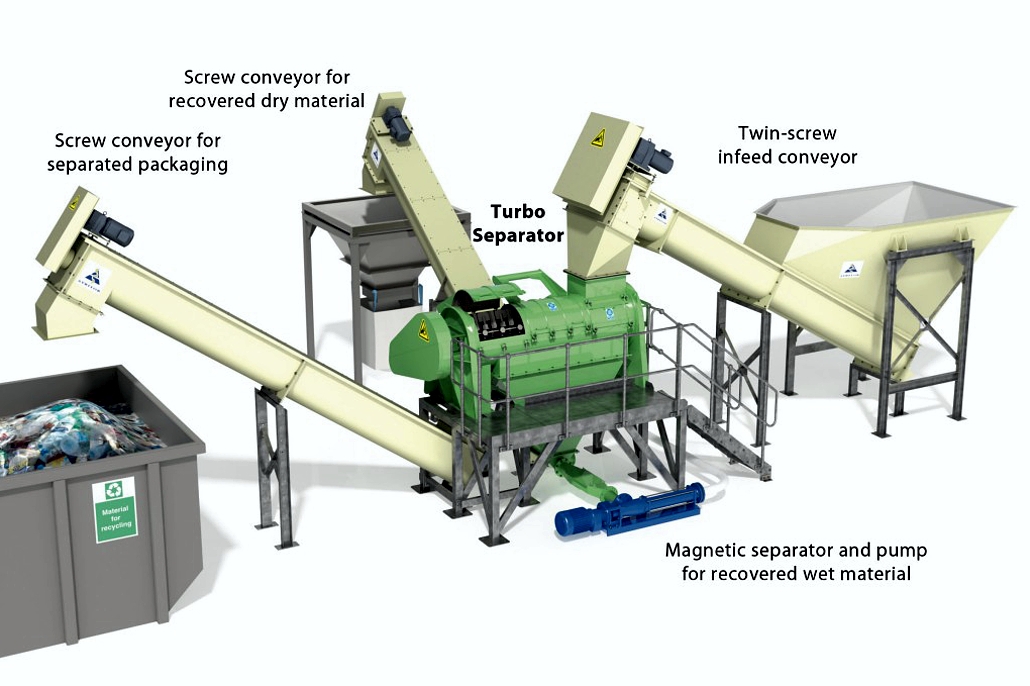

depackaging processing machine, waste handling whilst separating outer packaging from inside waste, enabling you to reuse and recycle waste that would have otherwise been sent straight to landfill. Waste food is a fast-growing issue for many companies, councils and manufacturers. Much of the waste generated cannot be accepted straight in to the manufacturers process; but requires some degree of separation or removal of outer waste packaging before it can be processed. The waste depackaging process is crucial in getting suitable food waste material into anaerobic digestion plants and is also used in putting food back in to animal feeds.

Biogen own and operate tiger machines at three of our existing food processing facilities; millerhill, halstead and basingstoke. The tigers operate at the front end of our food waste anaerobic digestion plants. They are designed to process the raw material at the front end to separate the organic and non-organic material. The non-organic material which is mainly packaging material goes for either disposal or re-use as an alternative fuel and the organic material (biomass) is pumped forward into a holding tank and then further on to pasteurisation and digestion in the sealed tanks to generate a methane gas for use in green energy production.

Doppstadt, a german company known for its shredders, grinders and trommel screens in the u. S. Composting market, also makes a screw press for food waste depackaging. A screw press is a device that accomplishes dewatering and food waste separation by continuous gravitational drainage. Dsp 205 screw press the dsp 205 couples a counter-rotating dual-auger mixing/feeding hopper with the screw press. Food waste enters the hopper, packaging is sheared open and the food waste then enters the screw press, where the auger in the press forces it against a pressing cone. This pushes the food waste through the screens. Foods and liquids drain through the 8 mm (5/16”) or 12 mm (5/32”) screen and the packaging and oversized materials are augered to the discharge port.

Food waste depackagers have evolved significantly since the early hammermill-based models. Wet digestion facilities handling commingled source separated food wastes from commercial and/or residential diversion programs look to these technologies to minimize problematic contaminants entering their digestion reactors. Composting facilities handling similar wastes might consider these machines as well worth the investment to reduce contamination removal costs as well as to create new tipping fee opportunities for industrial food product depackaging and recycling. Craig coker is a senior editor at biocycle and ceo of coker composting & consulting near roanoke, va. He can be reached at ccoker@jgpress. Com.

The Dominator Depackaging Machine

Tiger flower mix | tigridia. Tiger flowers, also known as mexican shellflowers, produce 3-petaled, low-growing blooms in a mix of vibrant colors, with striking spotted centers.

A close relative of the iris, these 3-6" wide blooms appear on straight, green blades. Azerbaijan batch mix plant manufacturer azerbaijan mixing. Dspa aerosol generator 11-4 can be used as a part of a highly effective fire extinguishing system. A dspa generator is non-pressurized and is installed inside a room or compartment that requires protection. The dominator waste depackaging machine is designed to remove outer packaging and reuse waste that would have otherwise been sent.

A close relative of the iris, these 3-6" wide blooms appear on straight, green blades. Azerbaijan batch mix plant manufacturer azerbaijan mixing. Dspa aerosol generator 11-4 can be used as a part of a highly effective fire extinguishing system. A dspa generator is non-pressurized and is installed inside a room or compartment that requires protection. The dominator waste depackaging machine is designed to remove outer packaging and reuse waste that would have otherwise been sent.

Rowan is a family run company who pride themselves on their integrity. With 40 years in the industry, they work with their customer’s best interests as our their priority. Rowan has developed the dominator waste depackaging machine, designed to separate outer packaging and its contents. Allowing the reuse of waste that would have otherwise been sent straight to landfill. The machine is also able to depackage wet waste. With the increasing problem of waste, many companies are finding ways of reusing this waste. Unfortunately, some of this waste can’t be accepted straight into the manufactures process and requires some degree of separation or removal of outer packaging.